6sl3040-0ma00-0aa1

update£º2015-03-22 11:23 Click£ºtimes

- brand

- model

- describe

A review of CU320, the control unit CU320 is a multi axis control unit, can control the 4 vector axis or 6 servo axes, or 8 V/F axis. The control unit is CU320, it is the drive system of the brain, is responsible for the control and coordin

introduce

A review of CU320, the control unitCU320 is a multi axis control unit, can control the 4 vector axis or 6 servo axes, or 8 V/F axis.

The control unit is CU320, it is the drive system of the brain, is responsible for the control and coordination of all modules in the entire drive system, complete control of current loop, velocity loop and even each axis position loop,

And between the same piece of CU320 control of each axis can exchange data with each other, that is, any one axis to other axis data read control unit, this feature is widely used among multi axes

Synchronous simple speed.

According to the number of connected with I/O module, peripheral axis control mode, the required function and different CF card, 1 pieces of CU320 can control the number of shaft is different.

Set as a speed control

Axis number, maximum control (refers to the band performance extension 1 CF card): usually 6 servo axes or 4 vector axis or 8 V/F axis. The actual control of the axle number and CU320 load (i.e.

Selected features) relevant, should be based on SIZER configuration software as the standard.

- servo axis and vector axis is not controlled by a CU320, namely the servo axis and vector axis cannot be mixed on a CU320, but the servo or vector can be compounded with V/F.

- the maximum output frequency and weak magnet: servo 650Hz, vector and V/F control for 300Hz. A maximum of 5 times of weak magnetic.

Set for position control

Maximum number of control axis (refers to the band performance extension 1 CF card): used for servo control, for a maximum of 4 axis; used as a vector control, a maximum of 2 axes, the number of control axis is not absolute,

Associated with the load of CU320, the specific control shaft shall be the actual application decision. Recommend the use of SIZER configuration software to decide can control the maximum number of axle.

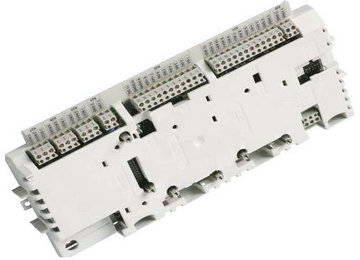

Two, the control unit CU320 provides the following interface

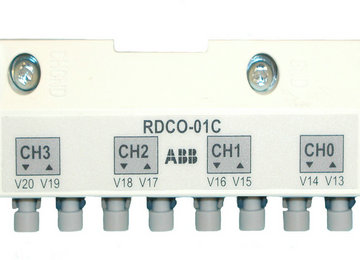

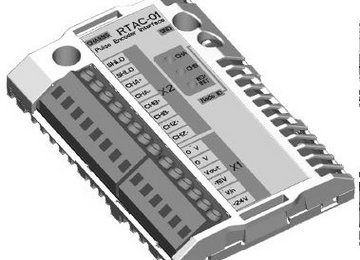

4 DRIVE-CLIQ slots, which can realize the communication with other DRIVE-CLIQ devices, such as sensor interface module, terminal expansion module etc.

The 1 accord with the PROFIBUS profile profidrive V4 interface

The 8 digital input parameter

8 the way parametric bidirectional digital input and output, of which 6 fast digital input

1 RS232 serial interface

The 1 basic operation panel BOP20 interface

1 a CF card slot

The 1 option slot (such as TB30 terminal module)

The 3 test socket and a reference ground

The 1 24V DC connector

The 1 PE interface

The 1 wire interface

Three, the control unit of the CU320 order data

ÉÏһƪ£º6SL3352-6BH00-0AA1 PSB board

more